Creating a high-gloss or reflective finish on a bronze sculpture requires a meticulous process that combines traditional craftsmanship with modern techniques. Artists begin by carefully polishing the bronze surface using progressively finer abrasives, starting with coarse sandpaper and ending with ultra-fine polishing compounds. This removes imperfections and creates a smooth base for the reflective finish.

After polishing, many artists apply a protective wax coating, often using Renaissance or carnauba wax, which enhances the metal's natural luster while providing durability. Some may opt for chemical patinas to create unique reflective effects, applying solutions like ferric nitrate or cupric nitrate before sealing with lacquer.

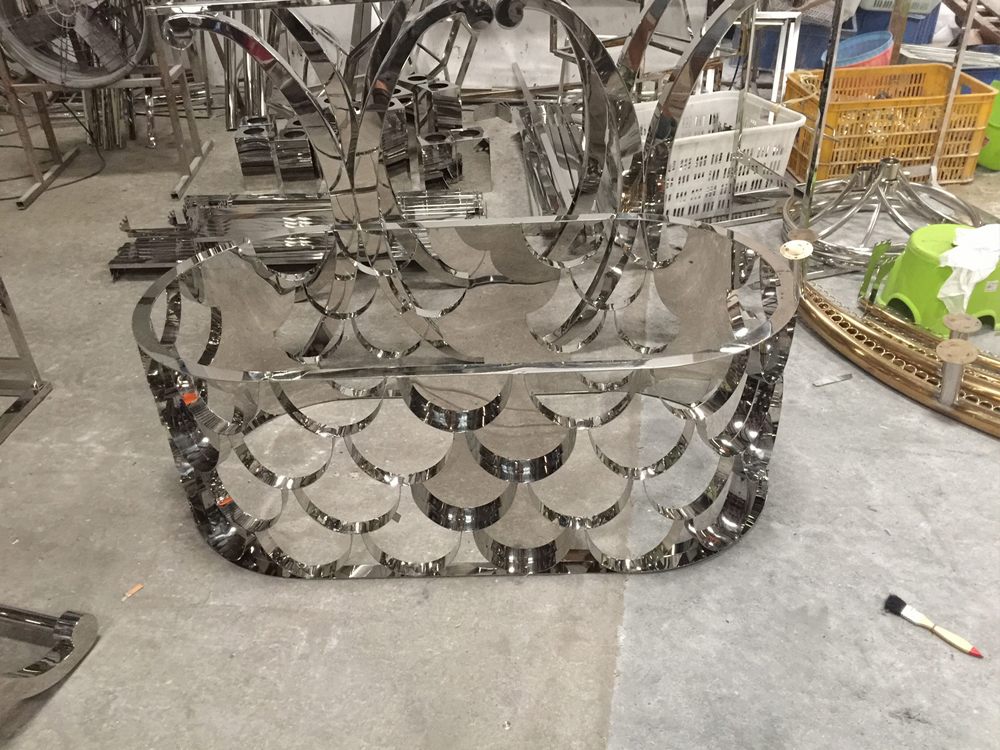

For mirror-like finishes, electroplating techniques may be employed, where a thin layer of chrome or nickel is deposited onto the bronze surface. Contemporary artists sometimes use power tools with buffing wheels to achieve consistent high-gloss results across large surfaces.

The final step always involves careful maintenance considerations, as highly polished surfaces require regular cleaning to preserve their reflective quality. This combination of ancient metalworking knowledge and modern finishing methods allows bronze sculptures to achieve stunning visual depth and luminosity.